Sawtooth Wave Jig

1,Overview

jigging is one of the relative new methods for gravity concentration. As a rougher or cleaner device, it is widely applied on the separation of gold, tin, tungsten, titanium, hematite, coal and other minerals due to its high processing capacity, large range of separation size and simplicity of operation and maintenance.

A traditional jig is mostly driven by eccentric circle, its jigging pulse curve is mostly sine wave, the upward or downward flow rate generated by the diaphragm movement and action time are almost same, therefore, it is not conductive to jigging bed dilation and stratification according to the proportion of mineral particles, and affects the sorting ratio and recovery of equipment.

Saw-tooth wave jig is a energy-saving gravity concentration device which is based on the traditional jig according to the distribution rule of jigging bed theory, its jig pulse curve likes the saw-tooth waveform which makes the upward flow faster than the downward; the upward flow time is short, the downward is long, which overcomes the shortcoming of upward flow, downward flow and action time produced by the sine-wave pulse curve, enhances the loose degree of the bed and alleviates the inhalation effects, then the heavy mineral particles in the ore are fully settlement, which enhances the sorting ratio and recovery of equipment. Compared with the sine-wave jig, the recovery of Sn increases 3.01%, W: 5.5%, Pb: 1.63%, Zn: 2.04%, respectively; water consumption is reduced by 30%-40%, site area is decreased 1/3, the stroke can be adjusted, dragging by the electromagnetic adjustable speed motor makes the pumping speed can be adjusted endlessly. Its performance reaches the domestic advanced level; it is one of the ideal energy-saving gravity concentration equipments.

2,Features

(1) High capacity,High concentration ratio and high recovery

(2) Fabricated with highest quality material

(3) Easy to install,operate and maintain

(4) The pulsation curve is saw-tooth wave shape facilitate heavy mineral to settling

(5) Saving water 30-40% than ordinary jig

(6) The pulsation speed very easy adjusted by regulator

(7) Suitable for roughing and desliming

(8) Can achieve a good result in processing such as placer gold,tungsten,iron,tin,hematite,cope,tantalum-niobium,titanium,manganese,barite,zirconium,chrome and gemstone etc.

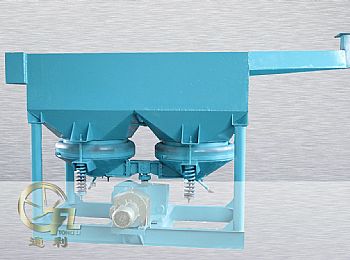

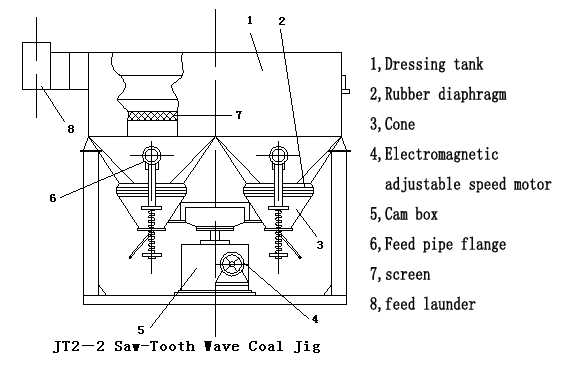

3,Structure

The structures of the saw-tooth wave jig are shown in figure

4,Types

The saw-tooth wave is divided into left-style and right-style according to the installation location of feed pipe flange. Standing on the ore feeding to look at the ore discharge, feed pipe flange on the left is left type, on the right is the right type.

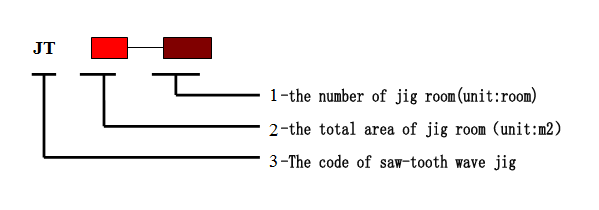

5,Model for example

The model of saw-tooth wave jig is made up of its code, dressing room area and the number of cell, its model is described as following:

6,Technical Specifications

|

Model

|

JT-0.15

|

JT-0.57

|

JT-1

|

JT2-2

|

JT3-1

|

JT4-2

|

JT5-2

|

||

|

Jigging

Chamber

|

Section

shape |

Trapezoidal

|

Trapezoidal

|

Trapezoidal

|

Tectangular

|

Trapezoidal

|

Rectangular

|

Trapezoidal

|

|

|

Length

×

wider

(mm)

|

200-400

×500 |

450-750

×950 |

450-900

×1500 |

1070×1070

|

960-2000

×1950 |

1510×1510

|

1200-2000

×3150 |

||

|

Column

number

|

single

|

single

|

single

|

single

|

single

|

single

|

single

|

||

|

Chamber

number

(one)

|

1

|

1

|

1

|

2

|

1

|

2

|

2

|

||

|

Single

area

(m2)

|

0.15

|

0.57

|

1

|

1.14

|

3.3

|

2.28

|

2.12

(single)

2.77

(double)

|

||

|

Aggregate

area

(m2)

|

0.15

|

0.57

|

1

|

2.28

|

3.3

|

4.56

|

5

|

||

|

Feeding

Particle

Size

(mm)

|

5

|

6

|

5

|

<10

|

<20

|

<8

or

<60

|

<8

or

<60

|

||

|

Processing

capacity

(t/h)

|

0.2-0.3

|

2-6

|

2-3

|

7.5-15

|

10-15

|

12-16

|

10-20

|

||

|

Water

consumption

(m3/h)

|

1-2

|

1-2

|

1-2

|

1-2

|

1-2

|

1-2

|

1-2

|

||

|

Diap

-hragm

|

Stroke

(mm)

|

4.2-30

90-180

|

12\17\21

|

15\20\25

|

12\17

|

10-47

|

6.5-26

|

15\20\25

|

|

|

Freque-

ncy (min-1)

|

|

60-200

|

80\100\120

|

60-200

|

80-100

|

80-150

|

80-110

|

||

|

Motor

|

model

|

YCT112-4B

|

YCT132-4B

|

YCT160-4A

|

YCT32-4

|

YCT-4B

|

YCT160-4B

|

YCT200-4A

|

|

|

power

(kw)

|

0.75

|

1.5

|

2.2

|

3

|

5.5

|

5.5

One

chamber

7.5

Two

chamber

|

5.5

One

chamber

7.5

Two

chamber

|

||

|

Dimensions

(mm)

|

734×960

× 1232 |

1560×850

×1550 |

2060×1112

×1890

|

3225×1550

×2150

|

2662×2000

×3030

|

4240×1990

×2750

|

3940×2006

×2580 |

||

|

Weight(kg)

|

284

|

612

|

914

|

1637

|

3260

|

3500

|

3854

|

||

7,Application Scenarios

| Production Scenarios | Production Scenarios | Production Scenarios |

|

|

|

| Customer Scenarios | Customer Scenarios | Customer Scenarios |

|

|

|