Shaking Table

1,Overview

6-S shaking table is one of the main equipments of gravity concentration. It is not only widely applied on separating tungsten, the tin, the tantalum niobium and other rare metals and the noble metal ore. Also widely used in separation for Gold, Silver, Tin, Columbium, Tantalum, Titanium, Barium, Tungsten, Iron, Chrome, Manganese, Zircon, Lead, Zinc, Mercury, Copper, Aluminum, etc. The shaker effective recycling granularity scope is 2-0.022 millimeters.

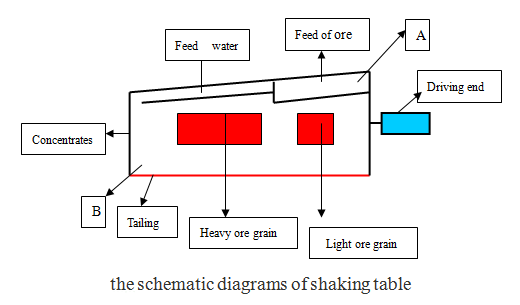

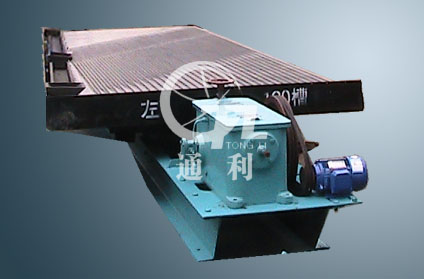

Beneficiation process of shaking table is carried out on the tilt table with riffle (Figure 1), the minerals are sent by the feed launder on the bed superior angle, simultaneously, it supplies horizontally the washing water from the feed water launder. Under the effect of gravity, crosswise running water momentum, inertia and friction force produced by the bed reciprocating asymmetrical movement, minerals are stratified by weight and size, and make the longitudinal motion along the bed and transversal motion along the tilt bed. Therefore, the proportion and the granularity different minerals fan out along the respective heading from A to B, discharged separately from the different areas of concentrate side and tailing side, and then divided into the concentrates, middling’s and Tailings.

According to different feed positions, shaking table is divided into right-type and left -type. Feed position of the right-type is on the right to its body; left-type is on the left.

2,Features

The characteristics of 6-S shaking table are high enrichment ratio, high efficiency of beneficiation, easy operation and convenient stroke adjustment. Changing the horizontal slope and stroke length, it can still maintain bed running in balance. Spring is placed in the box, so its structure is compact. Also it can eventually get the concentrates and tailings

(1) Easy installation , Simple operation , Long working life .

(2) High recovery ratio , High concentration ratio .

(3) Deck constructed of fiber glass .

(4) Three different decks to choose .

(5) Adjustable stroke length and speed .

3,Structure

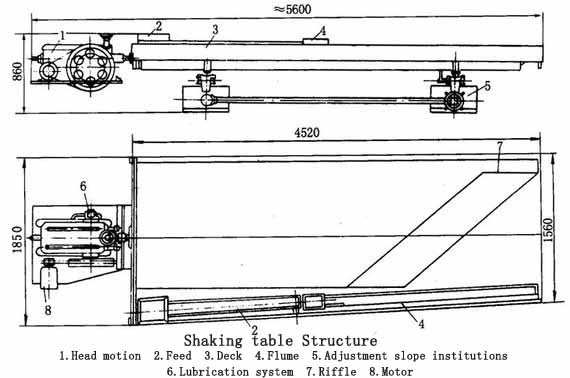

It is composed of head motion, motor, slop adjustment device, deck; feed chute, flume, riffle and lubrication system (figure).

4,Support Types

Installing foundation of 6-S shaking table have three styles; Ordinary foundation, small channel steel foundation, big channel steel foundation.

| Ordinary foundation | 10# small channel steel support | 28# big Channel Steel Support |

|

|

|

5,Technical Specifications

The 6-S Shaking Tables have three distinct deck designs available. The course ore deck is designed for recovering particles size from 0.5 mm to 2 mm; the fine sand deck is designed for recovering fine particles in the range of 0.074 mm to 0.5 mm; the slime deck is designed for recovering super extremely fine particles in the range of 0.05 mm to 0.074 mm.

|

Model

|

LS

|

LY

|

LY

|

LY

|

|

|

Screen Size(mm)

|

4500×1850×1560

|

3000×1620×1100

|

2100×1050×850

|

1100×500×430

|

|

|

Stroke

Length

|

mm

|

10-30

|

6-30

|

12-28

|

9-17

|

|

Frequency

|

T/min

|

240-420

|

210-320

|

250-450

|

280-460

|

|

Horizontal Slope

|

Degree

|

0-5

|

0-10

|

0-8

|

0-10

|

|

Feeding

Range

(mm)

|

Sand

Ore

|

-2

|

-2

|

-2

|

-2

|

|

Slime

|

-0.074

|

-0.1

|

-0.074

|

-0.074

|

|

|

Feeding Density

|

%

|

10-30

|

-

|

10-30

|

10-30

|

|

Capacity

(t/h)

|

Sand Ore

|

0.5-1.8

|

0.7-1.5

|

0.4-0.8

|

0.1-0.2

|

|

Slime

|

0.5-0.8

|

0.4-1

|

0.3-0.5

|

0.05-0.1

|

|

|

Water Consum-

ption

|

t/h

|

0.4-0.7

|

0.3-1.5

|

0.2-1

|

0.1-0.5

|

|

Motor

|

Model

|

Y70L-4

|

Y100L-4

|

Y90L-4

|

Y80L-4

|

|

Power

(Kw)

|

1.1

|

1.1

|

1.1

|

0.55

|

|

|

Rotation Speed

(r/min)

|

1400

|

1400

|

1400

|

1400

|

|

|

V-belt (mm)

|

A-2000

|

A-1033

|

B-2007

|

A-1245

|

|

|

Size(mm)

L× W × H

|

5600×1850×860

|

4075×1320×780

|

3040×1050×1020

|

1530×500×800

|

|

|

Weight(kg)

|

370

|

310

|

180

|

50

|

|

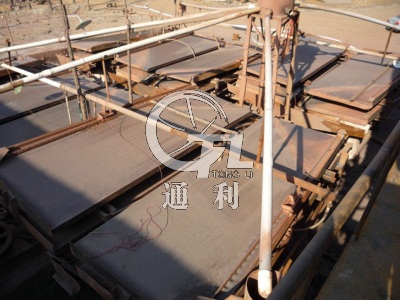

6,Application Scenarios

| Customer Scenarios | Customer Scenarios | Customer Scenarios |

|

|

|