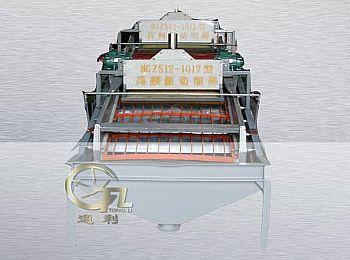

High Frequency Vibrating Screen

1,Overview

series of high frequency electromagnetic vibrating screen(for short electromagnetic screen) is a new type of material screening equipment, it uses a new vibration mode and transmission principle, making the use of electromagnetic vibrator drive system, to make the transmission system vibrating the screen ,after that the purpose is enhancing the sieve net screening efficiency. It has simple operation, stable performance, high efficiency, low power consumption, the characteristics of strong cleaning by itself.

It is used in grinding process of concentrator graded homework, under the appropriate of feeding concentrations, feeding particle size (200 mesh) , the difference between the demand level grain content screen size and feeding particle size is less than 30%,under this conditions, the screening efficiency is as high as 70% above. Due to the high screening efficiency, can greatly reduce cycle load and sieve grain that qualified level, so as to improve the capacity of mill processing power (general it can be improved the 5-10%), when controling things under strictly in the screening process on the screen size, can eliminate the harmful effects which separating the coarse size with concentrate grain quality , The pulp under the work in high frequency vibration sieve surface small amplitude, there is the role of density stratified according to function, high density and small particles is easy to settlement to the bottom of material, thus obviously improve the grade of concentrates.

2,Features

(1) The surface of screen is high frequency vibrating, the screen box is fixed, the working principle is fixed the balance between the elastic vibration of the system and the elastic force vibration force reaction in the screen box,so do the screen box is fixed.

(2) The surface of screen is high frequency vibrating, the frequency is 50HZ,the range of vibrating is 1-2mm, the strength of vibrating will be 8-10 times acceleration speed, compare with ordinary vibrating screen ,it is as high as 2-3 times, the characteristics of strong cleaning by itself, high screening efficiency,large capactiy, it is comfortable to screen, dehydration ,grade the size from 0.074-3mm in the slime material ore.

(3) The surface of screen consists of three different flexible screens, the bottom of steel wire core polyurethane nets,contacted with vibrating device directly,there are two layer of composite nets which make in the stainless steel ,the top of composite contact with material ore, the requirement of the top net is making sure the size depending on the screening system, the high opening rate in the screens, it owns a certain siffness.

(4) The sieve machine installation angle could be adjustment in convenient at any time , be adapted in different material properties and different screening homework. Regarding to the wet method of concentrator screening installation angle is generally in 25 degrees positive and negative 2 degrees range , dry screening installation angle is commonly in 33 degrees positive and negative 2 degrees range.

(5) The sieve machine vibration parameters by using the computer integrated control, can be software establishment to each of the vibration system vibration parameters, in addition to the general operating mode vibration parameters, and the continuous instantaneous strength vibrating at any time, keep clear to the screen hole to prevent blocking.

(6) The special design of the electromagnetic vibration system is using the rubber mainly vibration spring, rubber, rubber bearing spring hinge, it has long-term continuous operation reliable working, low consumption, each of the electromagnetic vibration power is only 0.15 KW, the dressing generally use the ZDS2020 type of high frequency electromagnetic screening, the installed power is only 1.2 KW. The sieve machine is belong to energy-saving products.

(7) Sieve machine have single channel and double channel , single layer and layers ect.many different structure forms, designing in modular, can design in flexible according to the specific applications .

3,Technical Specifications

|

Model

|

Screen Area(m²)

|

Dimension Size

L×W×H(mm)

|

Feeding Concentration (%)

|

Capacity

(T/H)

|

|

MVS2020

|

4

|

2625*2552*2100

|

30-40

|

6-20

|

|

MVS2420

|

4.8

|

2625*2952*2100

|

20-30

|

|

|

MVS2425

|

6

|

3025*2952*2100

|

24-36

|

|

|

NOTICE: The type we can make by customer requirement.

|

||||

4,Application Scenarios

| Customer Scenarios | Customer Scenarios | Customer Scenarios |

|

|

|