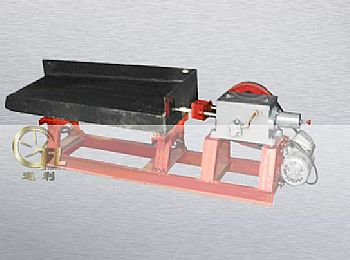

Laboratory Shaking Table

1,Overview

LY shaking Table is one of the commonly used equipment to conduct gravity concentration for feasibility study and test of ores for labs. And small beneficiation plant. It is applicable for separations of fine-grained and micro-grained rare metal, ferrous and non-ferrous metal, precious metal, coal and other minerals. It can carry out ore concentration operation independently and also can operate in conjunction with jig, screw separator, centrifugal separator and other equipment. The product is made by the only manufacturer designated by the former Ministry of Geology and Mineral Resources, in compliance with the Industrial standards.

LY Shaking Table is to make separations based on the difference of specific gravity of feed materials, reciprocating asymmetrical movement and the stratification performance of the inclined table surface in the lateral water flow with obvious zone of the minerals with different specific gravity on the table, hign quality of concentrates produced, convenient operation and adjustment and other features.

The table surface is constructed of ore sand or slime and is made up of glass fiber reinforced plastic or aluminum alloy.

2,General drawing and main structure

This machine mainly consists of table box, table surface, and table frame.

1,The table box is hyperbolic link mechanism. When the eccentric shaft rotates, it drives the upward and downward movement of the connecting rod. When the connecting rod moves downward, the toggle plate expands. The toggle plate on the right is supported on the supporting seat fixed with the draw bar while the toggle plate on the left is supported on the adjustable supporting seat(this seat can only move upward and downward),which is installed together with the supporting seat through special bolts. One end of spring is covered on the supporting seat and the other end is covered on the adjusting stud disk above the fixed sleeve.

2,The belt pulley passing the motor is driven to rotate. It drives the connecting rod and pushes downward the toggle plate to press the spring, as well as pushes the draw bar to carry the table surface forward. When the connecting rod moves upward, it drives the table surface to move backward under the action of spring tension. By doing it, the motion becomes continuous. The rotary motion becomes longitudinal straight reciprocating motion.

The stroke is obtained through the twisting of special stud. The whole mechanism is put in the shell of table box.

The bed surface is installed on the two cast iron beams. The beams are fixed on the sliding bearing and the bearings are fixed on the angle iron frame.

There is inclination angle for the table surface horizontally which can be from 0°to 10°.

Adjust the horizontal sliding bearing and hand wheel in the middle. At the one end of the hand wheel shaft which match the nut with arc groove. Such nut matches the connecting rod fixed on the draw bar. When the hand wheel turns to the direction of nut, it drives the rotation of connecting rod, draw bar, and table surface.

3,Technical Specifications

|

Model

|

LY3000×1460

|

LY2100×1050

|

LY1100×500

|

|

|

Bed size

|

mm

|

3000×1460×1260

|

2100×1050×850

|

1100×500×430

|

|

Stroke

|

mm

|

6~30

|

12~28

|

9~17

|

|

Frequency

|

t/min

|

300~450

|

250~450

|

300~450

|

|

Angle

|

0

|

0~10

|

0~8

|

0~10

|

|

Feed size(sand ore)

|

mm

|

≤2

|

≤2

|

≤2

|

|

Feed size(slime)

|

mm

|

≤0.174

|

≤0.174

|

≤0.174

|

|

Feed density

|

%

|

10~30

|

10~30

|

10~30

|

|

Capacity(sand ore)

|

t/h

|

0.4~1

|

0.4~0.8

|

0.1~0.2

|

|

Capacity(slime)

|

t/h

|

0.3~1.5

|

0.3~0.5

|

0.05~0.15

|

|

Water consumption

|

t/h

|

0.3~1.5

|

0.2~1

|

0.1~0.5

|

|

Power

|

kw

|

1.1

|

1.1

|

0.55

|

|

Size

|

mm

|

4075×1320×780

|

3040×1050×102

|

1530×500×800

|

|

Long×Wide×Higher

|

||||

|

Weight

|

kg

|

310

|

180

|

50

|

4,Application Scenarios

| Production Scenarios | Production Scenarios | Production Scenarios |